Screw Conveyor

Screw Conveyors: Efficient and Reliable Transportation Solutions

Screw conveyors, also known as auger conveyors, spiral conveyors, or screw feeders, play a critical role in industrial transportation processes. These systems effectively transport solid, powder, granular, and particulate materials between processes.

Their structure typically consists of a screw (helix) rotating inside a trough or tube, driven by a motor. As the shaft rotates, the material advances axially along the helix, facilitating transportation. This design offers simplicity and easy maintenance advantages, and it also allows efficient material discharge at various points.

Screw conveyors can be made from wear-resistant materials and, in special cases, can be manufactured using Hardox or stainless steel. Carbide coating may also be applied as required.

Primary applications of screw conveyors include:

- Dust collection systems

- Hygienic transportation of food materials (e.g., flour, sugar)

- Chemical material transport

- Transfer of materials requiring specific mixing ratios

- Locations requiring precise dosing feeds

- Cement factories

- Animal feed factories

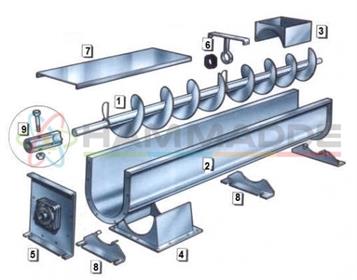

Main components of screw conveyors:

- Screw (Auger)

- Screw bed (Often a tube is used as a bearing)

- Inlet chute

- Outlet chute

- End cap, bearing

- Suspension bearing (Used in long screws)

- Top cover (Not necessary in tubular beds)

- Legs

- Couplings, gland packing, etc.

Advantages of Screw Conveyors:

- Compact structure

- Modular design

- Easy assembly and disassembly

- Capability to transport materials at high temperatures

- Speed-adjustable drive systems

- Ability to operate under high pressure

- Horizontal, vertical, and variable angle operation capabilities

Types of Screw Conveyors:

- Fixed pitch screws

- Rubber-winged screws

- U-type screws

- Tube-type screws

Contact us for more information about our reliable and efficient screw conveyor solutions for your industrial processes.