Industrial Boiler

It is called devices that convert chemical energy in boiler fuel to heat energy. The prepared fuels (oil or coal) are pulverized with air and sprayed into the combustion chamber. The heat released as a result of combustion evaporates the water in the boiler pipes. The remaining solid waste and slag fall into the water trough under the boiler and are then thrown out with tapes. The gases formed as a result of combustion are sent to the chimney around 110–160 C after the heat is taken thoroughly. The steam produced in the boiler is directed to the turbine.

Steam production; is the process of converting water into steam with the effect of heat. The water and steam temperatures in the water source are the same. This temperature is called lığı saturation temperature.. At constant pressure, a heat must be introduced to allow evaporation in a liquid source. This heat is called “latent heat” or “evaporation heat..

If the steam produced is at boiling point and does not contain water, this is called “dry saturated steam” and “wet steam orsa if it contains water. If the steam is heated to a point above the boiling point, it is called bir superheated steam..

Boiler Types

The boilers used in heating plants are classified as follows depending on various criteria.

1- According to the type of material used in boiler construction;

– Boilers with cast slice

– Steel boilers

2- According to the type of fuel used;

– Gas fired boilers (Natural gas)

– Liquid fuel boilers (Diesel, fuel iloil)

– Solid fuel boilers (hard coal, wood, etc.)

3- According to the pressure of the combustion chamber;

– Counter pressure boilers

– Boilers without counterpressure

4- According to heating fluid type;

– Hot water boilers

– Boiling water boilers

– Steam boilers

5- In terms of structural design of the boiler;

– Flame tube boilers

– Boilers with flame smoke tubes

– Boilers with smoke pipe

– Water tube boilers

6- In terms of the shape of the accident;

– Semi-cylindrical boilers

– Full cylindrical boilers

– Prismatic package boilers

In petrochemicals and refineries, boilers are generally used in two main types. These; flame tube boiler and water tube boiler.

Flame Tube Boilers

All the heat transfer in the flame tube boilers is made by the pipes (tubes) surrounded by water, through which hot combustion gases pass. Water and steam are located in the same section (barrel section). The steam output comes out of the drum. Examples of such boilers are steam locomotives and steam boilers and steam boilers through which the hot gas or hot liquid product passes through the tube in the process units.

Water Pipe Boilers

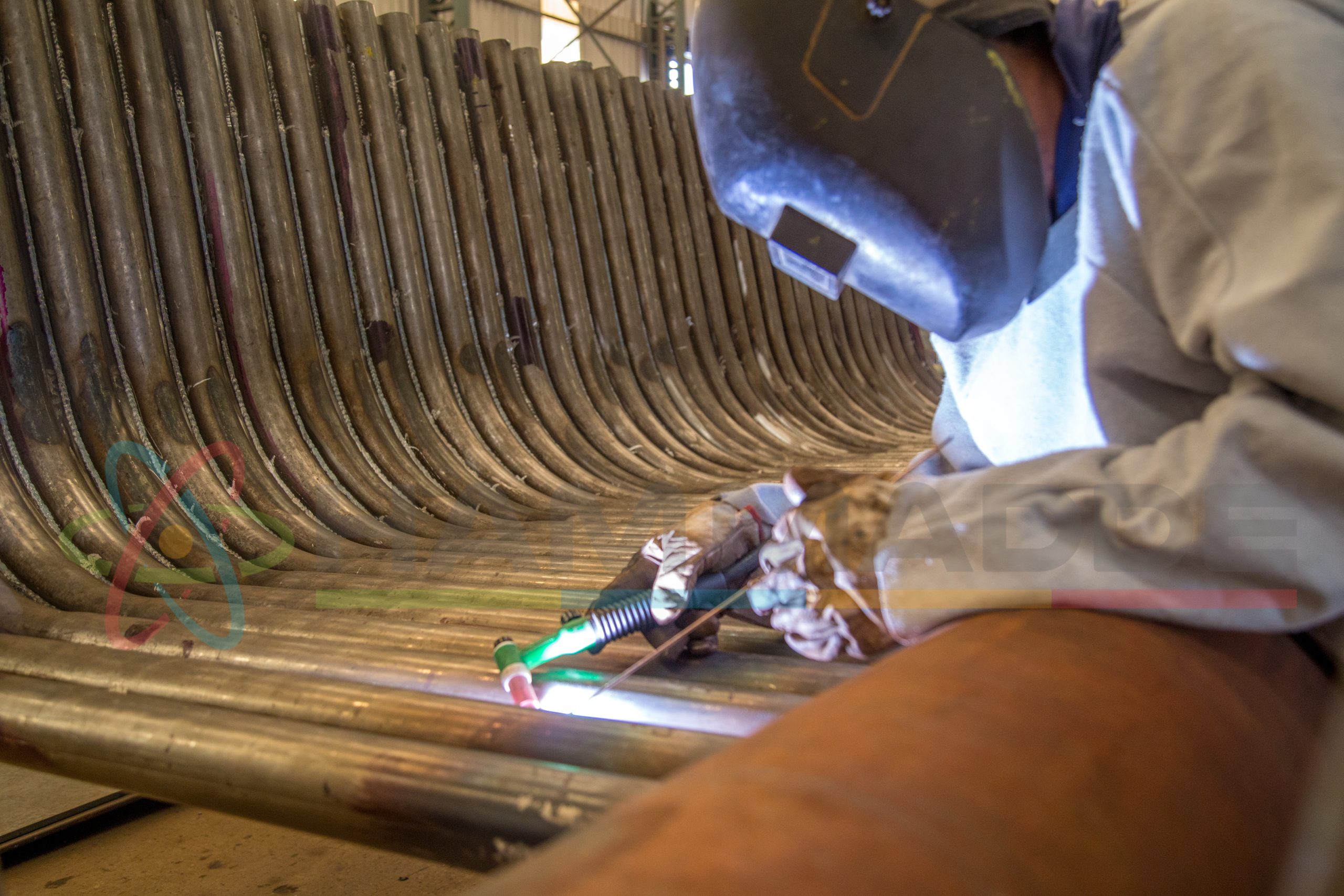

In boilers with water pipes, the combustion chamber is surrounded by tubes through which the water and steam mixture circulates. These types of boilers are used more widely in refinery operations than those with flame tubes. His designs have shown significant improvements in recent times. Vertical or near vertical tubes are used efficiently in both radiation (combustion chamber) and convection (combustion gases) zones. In addition, waste heat of hot flue gases is maximized by the use of economizers and air heaters.

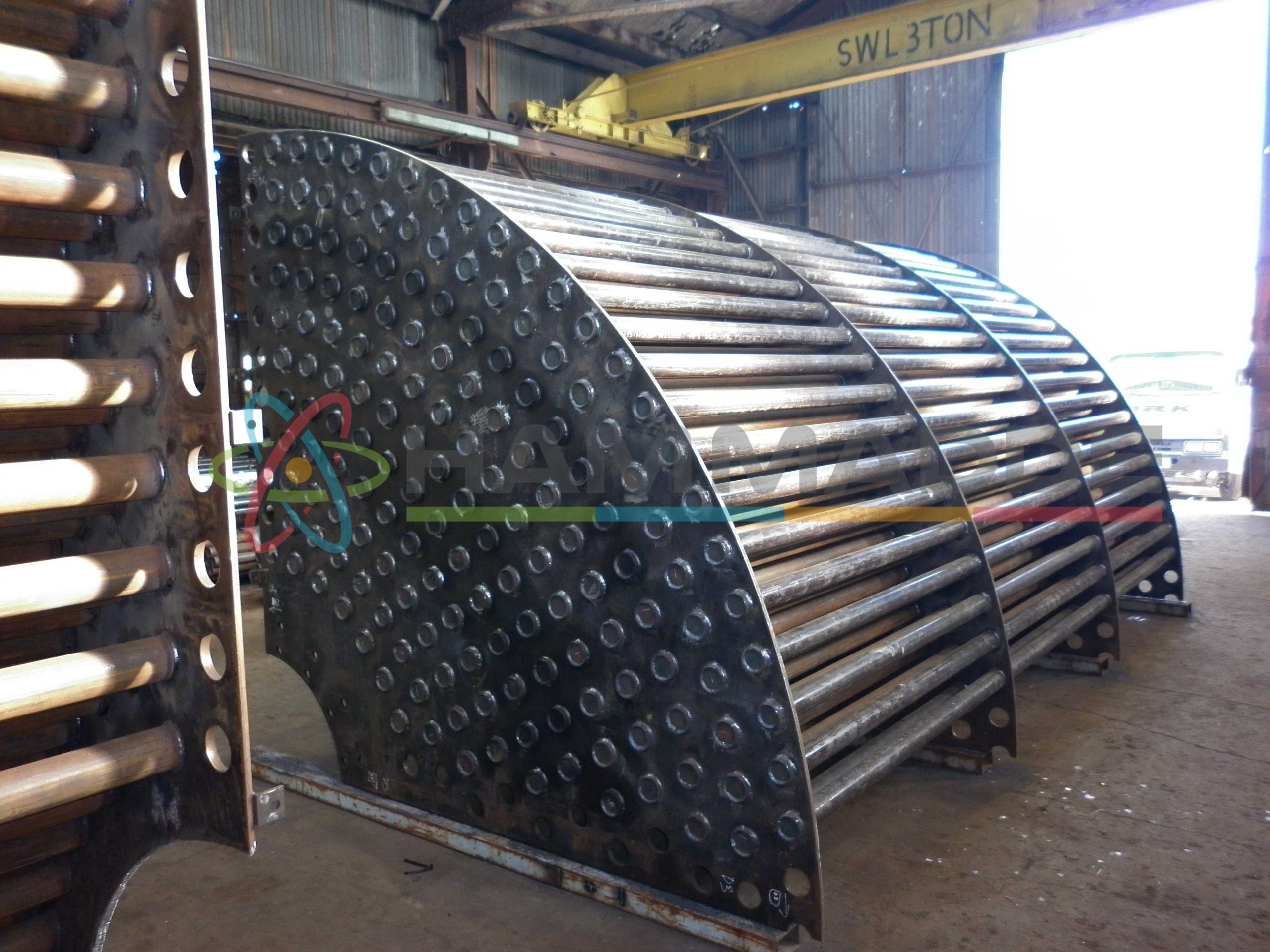

Packaged boilers are the type of steam boiler that has been widely used recently in refineries. The reason it is called as package is that these boilers are brought to their place in the refinery and assembled as a complete unit after they are made by the manufacturer. The limitation in the size of these boilers is determined by transportation difficulties. Another type of boiler is the boiler built on site. However, in terms of cost, it is about twice as expensive as package boilers. Boiler costs are generally rated per unit quantity of steam produced. Many packages of tubular water boilers have one of the following structural views. These are called “A”, “D” and “O” type boiler.

– “A” Type Boiler

Below are two small dramas and collectors. The upper drum is designed to provide steam and water separation. Most of the steam produced is formed in the central furnace wall tubes entering the drama.

– “D” Type Boiler

In this type of boilers steam arms enter around the drama water level. Börners are usually at the end of the wall. It is the most widely used boiler type in petrochemical plants.

– “O” Type Boiler:

Transportation problems are the most important factor in determining the size of such boilers. An “O” type boiler of the same capacity should be longer than other boiler types. Bases of “D” and “O” type boilers are usually covered with bricks. In all modern boiler constructions, the water tubes forming the combustion chamber wall are either tangentially connected or metal fin (fin) with gas passage sealing.

Boiling and Circulation

The aim is to produce steam by boiling. As the water begins to boil, it can be seen that in a bottom heated container, the steam emerges in the form of bubbles. It is replaced by bubbles and hot water, colder and steam-free water. In this way, a circulation is formed which transports th